Reuse & Production

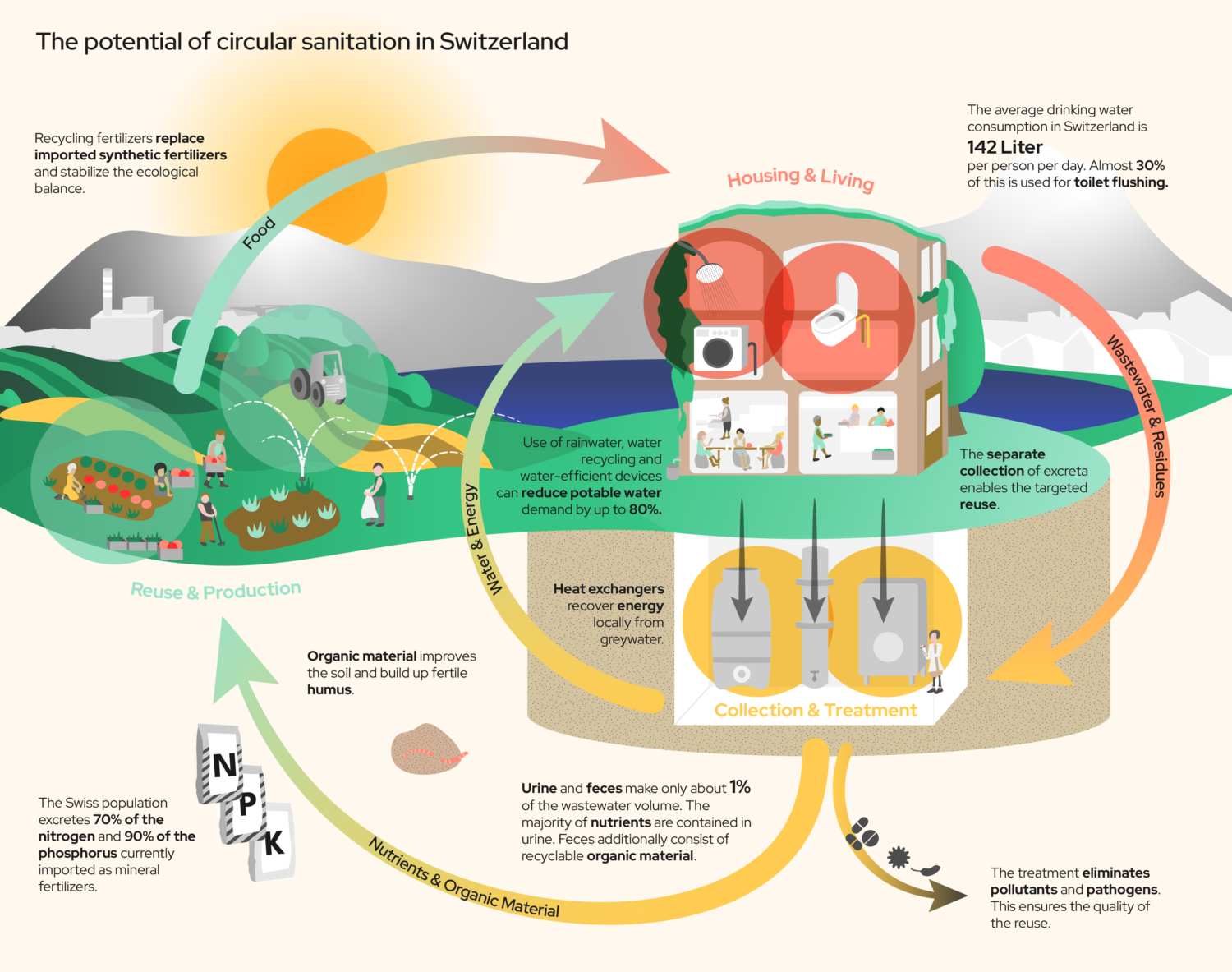

Circular sanitation systems allow the use of resources from wastewater. Wastewater contains nutrients, organic materials, energy and, of course, water – unless it is a dry toilet. Recycled water can be used locally for irrigation or as process water and is particularly well suited for the maintenance of green spaces or in agriculture. However, agriculture can also benefit greatly from the nutrients contained in wastewater: The targeted supply of nutrients in the form of fertilizers closes loops and reduces dependence on imported fertilizers.

Valuable nutrients

Nutrients such as nitrogen, phosphorus or potassium are essential for crop the growth of crops and are elementary components of fertilizers. In Switzerland, 100 percent of mineral fertilizers are imported: Around 45,800 tons of nitrogen and 4200 tons of phosphorus annually [1]! The production of fertilizers is problematic and has a major impact on our environment. While the production of synthetic nitrogen is responsible for an estimated two one percent of the world’s energy consumption [2], phosphorus is a limited resource that is extracted from critical sources at great energy expense [3]. Furthermore, phosphorus rock is increasingly contaminated with cadmium or uranium [4].

The problem with the sewer system

Nutrients and organic material in our excreta are currently diluted with wastewater, transported to the treatment plant via the sewer system, and mixed with pollution from industry and road runoff. Due to dilution, nutrient recovery and pollutant elimination require a lot of energy. While most of the nitrogen escapes unused into the atmosphere, the phosphorus is bound in the sewage sludge. Sewage sludge poses various environmental and health risks (heavy metals, micropollutants), which is why its agricultural use has been prohibited throughout Switzerland since 2006 (OC 2003 940, A 2.6 No. 2.1 Para 3 ORRChem; SR 814.81). Today, sewage sludge is fermented (production of biogas), then dried and incinerated. From 2026, phosphorus is to be recovered from the ash and recycled (VVEA, Art. 51 ADWO , Art. 15 ADWO). Furthermore, despite wastewater treatment plants, 1000 tons of phosphorus [4] and pollutants still end up in water bodies with the treated wastewater.

Circular economy involving nutrients from wastewater

Local recycling of nutrients reduces fertilizer import and stabilizes the ecological balanc. In addition, the reduction of fertilizer imports has a positive effect on the security of supply in case of fertilizer shortages. In fact, the Swiss population produces more than 80% of the nitrogen and 110% of the phosphorus currently imported as mineral fertilizers through its excreta. The composition of urine covers the nutrient requirements of plants particularly well. Urine is mainly rich in nitrogen and potassium and also contains traces of metals such as boron, zinc and iron. Feces contain nutrients such as phosphorus, calcium, and magnesium and can provide valuable organic material for soils [5, 6]. For example, compost from feces can increase soil fertility, store CO2, and improve soil nutrient and water holding capacity.

Due to the fact that almost one third of Swiss farms are located in agglomerations [7], extracting nutrients and organic matter from our excreta and water from used water through “urban mining” is particularly suitable for agriculture and contributes to a sustainable regional circular economy. However, there are significant health risks from human excreta and domestic wastewater such as pathogens and pharmaceutical residues. For this reason, appropriate treatment is essential, whereby pollutants and pathogens are removed. This guarantees the quality of the resource [6, 8].

Fertilizer and authorization

Because of the valuable nutrients and organic material, human excreta should be recycled. There are various processes for producing such recycled fertilizers from urine, from feces with or without urine content, from dry toilet contents or from other novel sanitation systems.The aim of the treatment is to remove pollutants and deactivate pathogens. In this way, stable and storable fertilizers are produced, which cause only minor environmental losses due to offgassing, seepage or erosion. Accordingly, these have advantages over conventional fertilizers such as mineral fertilizers or animal manure. In Switzerland, there is currently still a lack of clear regulations regarding the marketing of such recycled fertilizers. VaLoo is actively working to create enabling legislation. In 2018, Aurin®, a liquid fertilizer made from urine, received the first approval for the fertilization of crops and ornamentals and is available on the market.

Water reuse

Treated wastewater can also be used for irrigation, which has great potential, especially in times of prolonged drought. Water reuse can complement stormwater management and help develop the city as a sponge city (sponge city project vsa). However, it is currently foreseen that wastewater must be connected to the sewerage system (GschG, Art. 11 WPA ). The treated water from the wastewater treatment plant must be discharged into a water body (GschV, Art. 6-9 WPO). Since the cantons are responsible for enforcement, exceptions can be granted to reuse the water for toilet flushing or irrigation (Equilibre, KREIShaus). It is recommended that project initiators and the canton agree on monitoring, which ensures the quality (e.g. Template by OCEau CT Geneva).The nutrients we flush down the drain and the water we consume every day are valuable resources. Using them as fertilizer, process water and irrigation water contributes to a consistent circular economy and a more sustainable food system.

Text: Louise Carpentier

Editing: Dorothee Spuhler, Gina Marti

Readings

Nährstoffwende – Discussion paper and examplesP2Green (EU, since 2022) Closing the gap between fork and farm for circular nutrient flows

Ocapi (France, since 2015) Organisation des cycles Carbone, Azote, Phosphore dans les territoires

zirkulierBAR (Germany, since 2021) Nährstoffe aus verzehrten Lebensmitteln zurückgewinnen und diese im Sinne einer nachhaltigen regionalen Kreislaufwirtschaft wieder der Landwirtschaft zuführen

Prof. Dr. Morgenroth (2024), Wasserwiederverwendung Schweiz

van den Broek (2024), Opportunities and challenges of using human excreta-derived fertilizers in agriculture

References

[2]: Patil, B. S., et al. “Plasma N2-Fixation: 1900–2014.” Catalysis Today, vol. 256, 2015, pp. 49–66, https://doi.org/10.1016/j.cattod.2015.05.005.[3]: SRF Treffpunkt (Audio) [4]: Binder C. R., de Baan L., Wittmer D. (2009); Phosphorflüsse in der Schweiz. Stand, Risiken und Handlungsoptionen. Abschlussbericht. Umwelt-Wissen Nr. 0928. Bundesamt für Umwelt, Bern. 161 S. https://www.infothek-biomasse.ch/images//203_2009_BAFU_Phosphorfluesse_in_der_Schweiz.pdf.

News about Reuse & Production

Event

20.01.2026 |

Dübendorf

PEAK-VaLoo basic course B37/26

Event

21.06.2024 |

Trub

Sanitärwende zur Sonnenwende: Führung Balmeggberg